Seed drill designed for small and medium farms. An essential advantage of the machine is even weight distribution, which helps to decrease power requirement of the tractor by 20 percent. Seed drill FT2 offers several possibilities of use with seed and fertilizer application. FT2 is primarily designed for combination with Pneusej seed drills.

The sowing machine is equipped with a tank with a capacity of 1600 l, (optionally 2200 l) which offers several uses, namely:

- front mounted seed hopper with capacity 1600 liters, combined with rear mounted coulters. It is possible to order an optional 2200 liters. The rear part is produced in working width 6 m – 12 m.

- front mounted hopper designed as a fertilizer tank with a combination with precision planters (max. 16 rows) and with machines for soil tillage up to 12 m working width. Hopper surface as well as parts of dosing unit are produced to withstand different types of fertilizer.

- front mounted seed hopper can bee divided to two parts as optional. Hopper 1600 liters can be divided to seed 800 l and fertilizer 800 l, hopper 2200 liters can be divided to seed 1100 l and fertilizer 1100 l.

Main

part of the machine

Dosing system

Central feeding is the heart of the whole system. It enables maximally precise metering of sowing in the range – 380kg per hectare. The central completely closed seed roller precisely proportionates the seed and supplies it to the injector canal, where it is mixed with a stream of air from the ventilator, and then it goes to the distributor through the diffusion tube, and goes further into the individual sowing coulters through the seed tubes. The residual seed in the hopper is minimal and can be spilt out by means of discharging flap.

Electronic and control units

Drillmat III

In standard equipment is the drive of dosing unit solved by drive of stepping wheel. In this case, the customer can use the simple electronic and control device Drillmat III, which offer : signaling of seed level, electronic hectare counter, ventilator speed signaling, dosing unit control, 2×2 el. magnetic shut off valves Accord for tramlining.

RDS iSOCAN Artemis

The seed drill FT2 can be equipped with the electronic drive of dosing unit RDS ARTEMIS. This electronic and control device offers connection for up to 4 motors. Simple and accurate calibration is performed using the calibration button, another big advantage is to increase or decrease the seed rate while driving. ISOBUS compatibility is becoming a big phenomenon today, this device is not lagging behind and is ISOBUS compatible. In addition to the above advantages, RDS Artemis also offers features such as: signaling of seed level, electronic hectare counter, ventilator speed signaling, dosing unit control, 2×2 el. magnetic shut off valves Accord for tramlining, radar for speed sensing, ISOBUS compatible.

1. Drive of ventilator

In standard equipment is the seed drill to use with mechanical drive of ventilator 1000 RPM, which is specific for low cost maintenance. In additional equipment is possible to equip the machine with hydraulic drive of ventilator, that improves user comfort and ventilator life.

2. Hopper

Seed drill is in standard equipment with hopper of capacity 1,600 liters. It is possible to add the hopper capacity for another 600 liters. Front mounted seed hopper can bee divided to two parts as optional. Hopper 1600 liters can be divided to seed 800 l and fertilizer 800 l, hopper 2200 liters can be divided to seed 1100 l and fertilizer 1100 l.

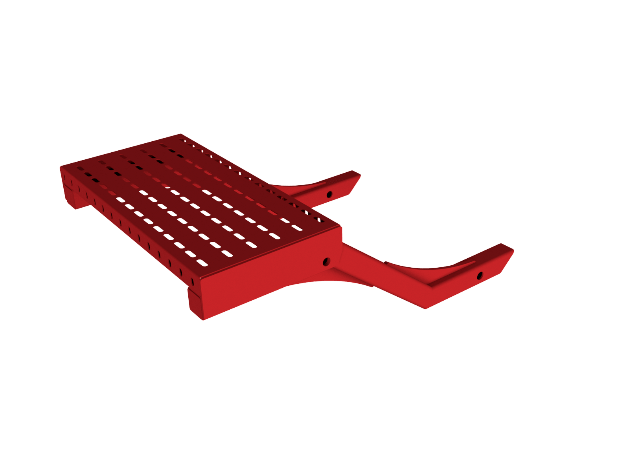

1 - step stair

is suitable for type FT2 and provides a convenient and secure availability of the seed hopper. Thank to the stair, even filling with bags is not a problem.

| Technical parameters | FT2 |

|---|---|

| Feed opening (m) | 1,85x1,04 |

| Filling height (m) | 1.7 |

| Working speed (km/h) | 5-12 |

| Power required (kW) | 97 |

| Power required (HP) | 130 |

| Weight without seed (kg) | 650 |

| Fan drive | 1000 RPM or hydraulic drive |

| Hopper (l) | 1600 l or 2200 l |

| Connection via lower link | Cat. II, III |

| Precision planters rows (pcs) | 2x6 or 2x8 |